Welcome to Jain Irrigation Systems Ltd.

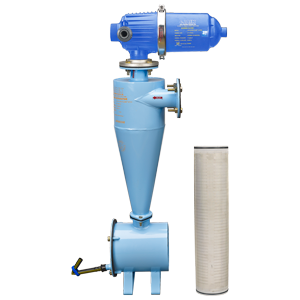

Filtration Systems

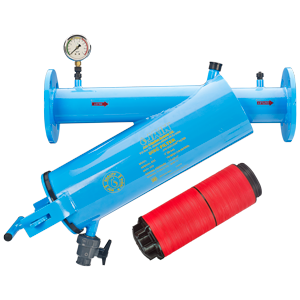

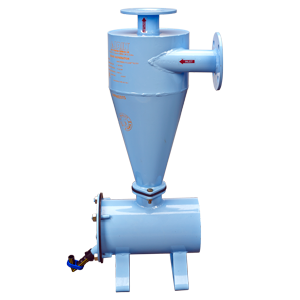

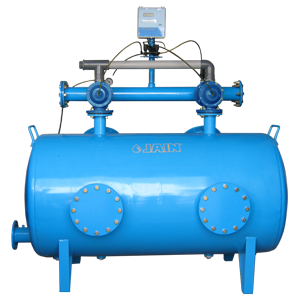

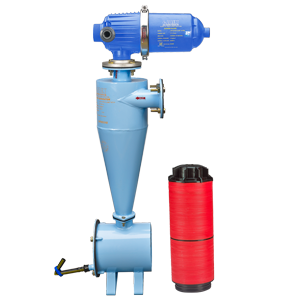

Filtration station is the heart of a micro irrigation system. No matter how clean the input water is, a filter is an insurance to guard against debris entering the irrigation system. Even small particles in the water can cause drip emitters to become choked. The types of filters generally used are: Hydrocyclone / Sand Separator, Media filter (sand filter) and Compulsory filter (screen/disc/turbo clean). The types of filter to be used in the system depend on the quality of input water and their capacity depends on the design and discharge. Essentially, Hydrocyclone filters/ Sand Separators are used for sand particles which probably come from running water sources like rivers, canals, bore wells etc. Media filters are used for biological impurities such as algae /slimy things etc.

The pressure at the inlet of the filter should be optimum (depending upon the type of system) to obtain uniform discharge through the drippers and to minimize clogging or choking of laterals and drippers.

The pressure difference between the inlet and outlet of a filter is an indicator that suggests whether filters need cleaning. If the pressure difference is more than 0.3 kg/cm² (3 m of water; for screen and disc filter), it means the filter needs cleaning. The pressure difference between the inlet and outlet of a filter can be checked using a pressure gauge provided with separate pressure check assemblies for inlet and outlet respectively.

Why Filters ?

- Water is not found in its purest form in nature. It is always contaminated with physical, chemical & biological impurities.

- Proper filtration is of much importance to prevent low pressure diffuser like emitters from clogging. Our wide range of water filters are standing like watchdogs to protect your system from clogging hazards.

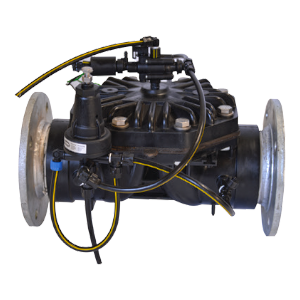

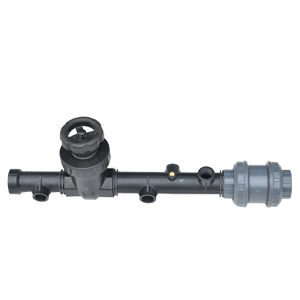

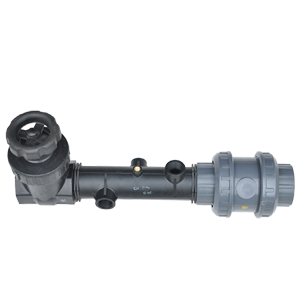

Jain Polymer Filters

- With introduction of new and improved polymers, plastic has achieved similar strength that of metal.

- Polymer material is lighter.

- Manufactured from special plastic alloy material which gives very high stiffness, toughness, heat and impact resistance.

- Excellent chemical and weather resistance.

- Ribbed body construction, designed to withstand water hammer and surges in the pipe line.

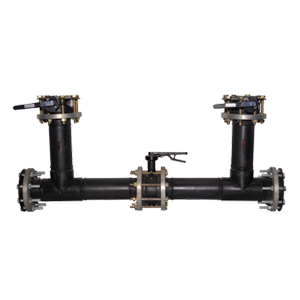

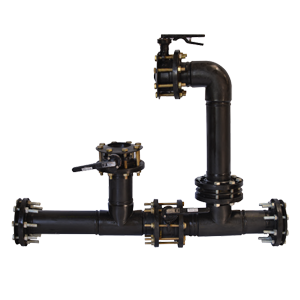

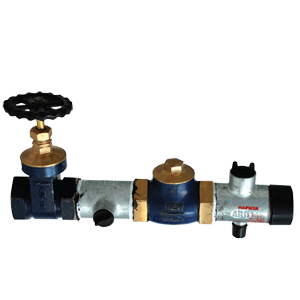

- For Multiple Filters / Batteries Options with; -Specially designed manifolds suitable for installation of multiple units of Jain Super Flow Plus Disclean filter.

- Coated Inlet/outlet manifold with more than 150 micron deep blue coloured epoxy powder from both inside and outside surface for protection against corrosion and weather effects.

- Can also be supplied with light weight, durable HDPE manifold or chemical resistant stainless steel manifold. Please specify while placing the order.

- Equipped with high performance, durable valves which can provide consistent performance over the years.

2018_opt.png)