Welcome to Jain Irrigation Systems Ltd.

Ramthal - Integrated Drip Irrigation Project

-

No of Beneficiaries

7382

-

Client

-

-

Year

2017

-

Area

30381

-

Location

Hungund, Karnataka

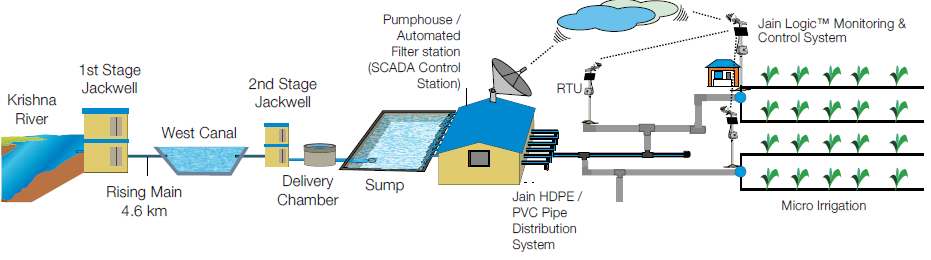

Concept

In this project, water is lifted from Narayanpur reservoir and delivered to main delivery chamber. Water is then distributed over 30381 acre of area through 12 numbers of advanced variable frequency drive pumps. Water is filtered through online self-cleaning automatic ‘Smart Clean’ filters to ensure only clean water for the drip system. Water is then conveyed to the farmers’ field through a network of HDPE/PVC pipe.

The pressure and flow of the system is controlled through sensors and PLC system. Entire pumping and filtration system is controlled and monitored through a SCADA software. Every farmer is provided with automation valve which delivers water to his field. These valves get command to operate through a wirelessly controlled ‘IrriConnect’ RTU. System is monitored and sends data through AIOT (Agri-IOT) enabled devices connected to a central server.

Jain irrigation’s most popular Five Star rated clog resistant driplines are laid on the fields to deliver the lifted water directly near the root zone of the crops.

Operation of the drip irrigation system is remotely monitored and controlled by ‘Jain Irricare’ - web operated wireless controlled irrigation management and advisory system. Jain Irricare has got excellent user management facilities. Farmers gets weekly and daily updates about his irrigation schedules, Valve ON/OFF events. He can access and view the operation on his field any time. Farmers also gets advisory messages about crop he has sown, agronomical practices, do’s and don’ts, maintenance of the system etc.

All the data is securely stored on Jain Irrigation’s Cloud servers. Daily/monthly reports are generated for schedule operations and water accumulations. The project is conceptualized, designed, executed, commissioned, operationalized and maintained by Jain Irrigation.

Objectives of Automation System

● To control the operation of each individual farmer’s valves in each block according to predefined irrigation schedule.

● To flush the screen filter by opening the drain valve of screen filter.

● To monitor the flow of water through each block.

● To monitor pressure fluctuations for each block.

● To identify malfunctioning and generate alarms on the basis of flow and pressure data for each block.

● To control the operation of pumps for each zone.

● To control the flushing of filters at main filter station.

● To control the operation of control valve to regulate the flow of each zone.

● To control and monitor the pressure at each zone inlet.

● To monitor the water level at main sump.

The unique fully automated system is designed in this project which take cares of farmer level control with pressure regulation and monitor flows in the system schedules. This system operates and controls the pumping system as per predefined and pre-set water level in the source. The automation system monitors and controls through field sensors like pressure and flow transmitter. Controlling and monitoring of the system is possible through internet. It provides the flexibility to monitor the system from anywhere and anytime where the network is available. It also controls the flushing of filters at the main filter station. It identifies malfunctioning and generates alarms. A unique feature of this automation system is that it offers flexible access to multiple users at a time. (E.g. The farmer can access his data, field technician can monitor the faults, project engineer can plan a schedule or monitor schedule, Govt. Officers can monitor system performance by sitting in their office etc..) Every farmer receives SMS alerts for valve ON/OFF, Schedules, Crop alerts and agronomical advice through user management system. It has strong backup support as the data gets stored in the server.

Ramthal Schematic Layout